Plastic is one of the greatest forms of waste. Even when it is recycled, it is often “down cycled” from high value, long lived products to low value, short lived products. This is because each plastic type requires its own recycling process, thus, a small amount of contamination can result in strong reduction in desirable properties, such as strength.

Vink is an industrial plastics distributor. Companies, such as ASML, purchase plastic from Vink, process it into their products, and return the waste plastic to Vink. By obtaining agreement between end user, and suppliers, such as Mitsibushi chemicals, Vink has set up a circular supply chain, where the end user agrees to sort the waste plastics on site.

Project description

Vink faces a number of challenges, but for this project, we want to focus on a single part of the process. Vink, in partnership with the Circular Plastics Factory, have a process for fully recyclying polycarbonate. Polycarbonate is often used in place of glass: it is very strong, and highly transparent. But, polycarbonate also scratches easily (compared to glass). To prevent scratches, polycarbonate is often coated with an anti-scratch layer. This layer is impossible to directly see, and is enough to contaminate the recycling process.

At the moment, the Circular Plastics Factory will only recycle polycarbonate that has a protective film (the same type of film that is placed on appliances to protect from damage) that contains information about the coating. If the end user has removed the entire protective film from a sheet, that plastic cannot be recycled into a new polycarbonate sheet and must be down-cycled.

Our job is to develop a measurement system that can detect the presence of the anti-scratch layer. At this stage, the device does not need to scale to industrial use, but, the end purpose (high volume throughput) should be kept in mind. No technique is off-limits at this point.

Project result

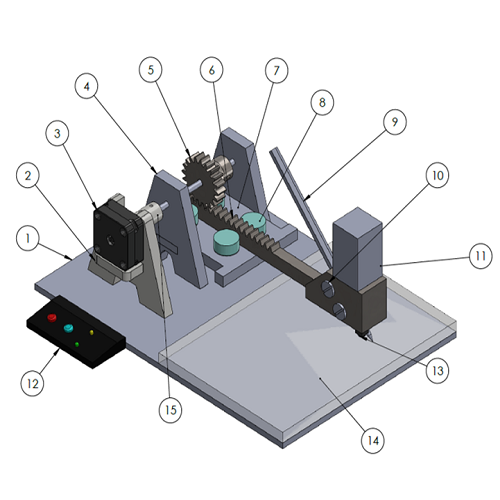

We have developed a method to detect the presence of the anti-scratch layer by processing the sound that is produced by scratching the materials under test. A prototype scratching device was developed as well. This device comprises a stepper motor to move the scratch pen, a scratch pen at a 45 degree angle, a microphone that records the sound produced by the scratch, and a few buttons to control the moving part.

The company Vink is interested in a follow-up project to advance our method and prototype towards industrial application.

Video

Acknowledgement

The Fontys project team would like to thank the company Vink Dutch for their guidance and knowledge sharing during the project.